close

Choose Your Site

Global

Social Media

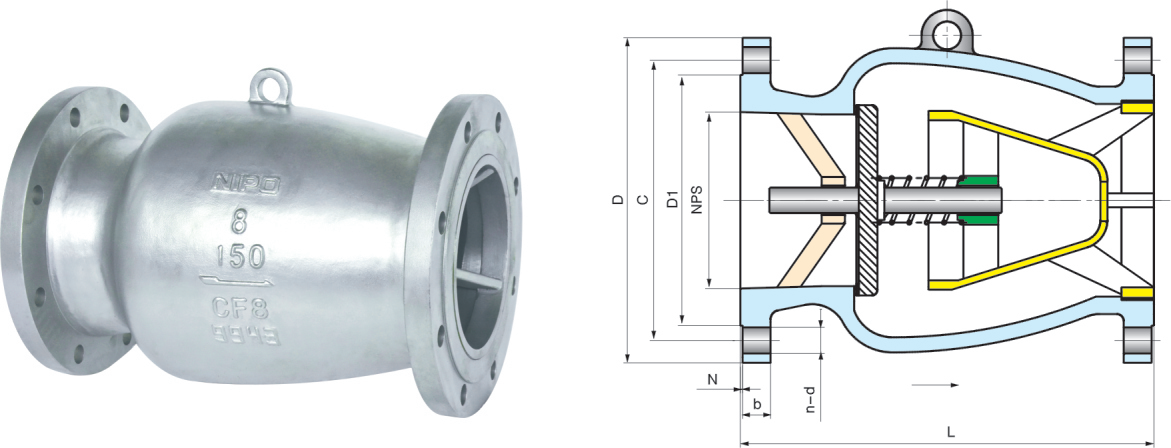

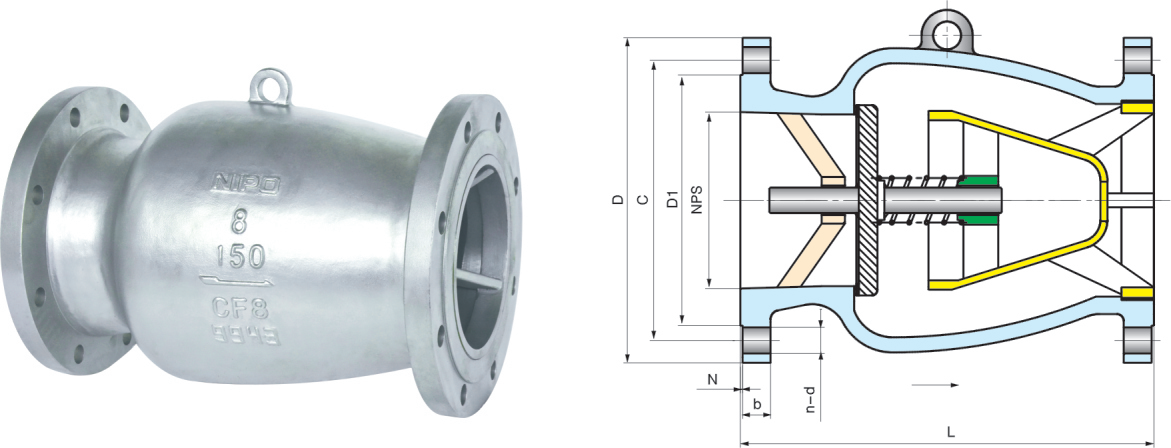

Except of the general function of check valve,the axial flow check valve has the advantages of small noise and lower impact with the using of a spring. With the axial flowing structure, the valve has characteristic of small fluid resistance, great flow capacity, and small outer dimension which makes this valve a wonderful choice using on the outlet of pump in pipeline system transporting oil and gas. it is used on the pipeline transporting oil, gas, water and etc. For non-return demanding condition.

Except of the general function of check valve,the axial flow check valve has the advantages of small noise and lower impact with the using of a spring. With the axial flowing structure, the valve has characteristic of small fluid resistance, great flow capacity, and small outer dimension which makes this valve a wonderful choice using on the outlet of pump in pipeline system transporting oil and gas. it is used on the pipeline transporting oil, gas, water and etc. For non-return demanding condition.

1.One-piece body,small weight, good strength, and easy maintenance.

2. The thrust force of spring enables the valve stayed in closed position even without the force of medium.

3. Wonderful sealing carrier makes the valve able to be installed at any direction, and the disc can tough the seat sealing perfectly.

4. Axial flow structure and accurate flowing passage enables little pressure loss, stable medium flowing, and non cavitation erosion. The disc returns to the sealing position with the force of spring and sub-pressure caused by medium flowing. So there is No. Direct impact of the

medium onto the back side of the disc, Axial flow check valve is a low-noise type.

5. The special structure and surface treatment of the disc carrier and pin eliminates the phenomenon of valve sticking. it can close and open evenly to avoid the common defects of disc can not stay in the center of sealing position because of the gravity of disc. So the valve has wonderful and lasting sealing effect.

6. In closed position, and accurate design makes the thrust force of spring is a little bigger than the force of disc's gravity plus the friction force between disc and sealing ring. And the disc can return to its sealing position under low pressure despite of any installation position so as to protect the operation of pump.

1.One-piece body,small weight, good strength, and easy maintenance.

2. The thrust force of spring enables the valve stayed in closed position even without the force of medium.

3. Wonderful sealing carrier makes the valve able to be installed at any direction, and the disc can tough the seat sealing perfectly.

4. Axial flow structure and accurate flowing passage enables little pressure loss, stable medium flowing, and non cavitation erosion. The disc returns to the sealing position with the force of spring and sub-pressure caused by medium flowing. So there is No. Direct impact of the

medium onto the back side of the disc, Axial flow check valve is a low-noise type.

5. The special structure and surface treatment of the disc carrier and pin eliminates the phenomenon of valve sticking. it can close and open evenly to avoid the common defects of disc can not stay in the center of sealing position because of the gravity of disc. So the valve has wonderful and lasting sealing effect.

6. In closed position, and accurate design makes the thrust force of spring is a little bigger than the force of disc's gravity plus the friction force between disc and sealing ring. And the disc can return to its sealing position under low pressure despite of any installation position so as to protect the operation of pump.

Design Basis | GB | API/ASME | |

Design Standard | GB/T 21387 | API6D ASME B16.34 | |

Face-to-Face | GB/T 12221 | API6D ASME B16.10 | |

Connection End | Flanged | GB/T 9113 | ASME B16.5 |

Materials | NACE MRO175 | ||

Test and Check | GB/T 26480 | API598 | |

The valve connection end standard designed and manufactured according to user requirements. | |||

Main Parts and Materials Conventional Type

Part Name | Carbon Steel | Low Temp Steel | Stainless Steel | |||

GB | ASTM | GB | ASTM | GB | ASTM | |

Body | WCB | A216-WCB | LCB LCC | A352-LCB A352-LCC | CF8 CF8M | A351-CF8 A351-CF8M |

Disc | WCB | A216-WCB | LCB LCC | A352-LCB A352-LCC | CF8 CF8M | A351-CF8 A351-CF8M |

Guiding part | WCB | A216-WCB | LCB LCC | A352-LCB A352-LCC | CF8 CF8M | A351-CF8 A351-CF8M |

Sleeve | 12Cr18Ni9 | SS304 | 12Cr18Ni9 00Cr17Ni12Mo2 | SS304 | 12Cr18Ni9 00Cr17Ni12Mo2 | SS304 SS316 |

Spring | SS304、SS316、InconelX-750 | |||||

Design Basis | GB | API/ASME | |

Design Standard | GB/T 21387 | API6D ASME B16.34 | |

Face-to-Face | GB/T 12221 | API6D ASME B16.10 | |

Connection End | Flanged | GB/T 9113 | ASME B16.5 |

Materials | NACE MRO175 | ||

Test and Check | GB/T 26480 | API598 | |

The valve connection end standard designed and manufactured according to user requirements. | |||

Main Parts and Materials Conventional Type

Part Name | Carbon Steel | Low Temp Steel | Stainless Steel | |||

GB | ASTM | GB | ASTM | GB | ASTM | |

Body | WCB | A216-WCB | LCB LCC | A352-LCB A352-LCC | CF8 CF8M | A351-CF8 A351-CF8M |

Disc | WCB | A216-WCB | LCB LCC | A352-LCB A352-LCC | CF8 CF8M | A351-CF8 A351-CF8M |

Guiding part | WCB | A216-WCB | LCB LCC | A352-LCB A352-LCC | CF8 CF8M | A351-CF8 A351-CF8M |

Sleeve | 12Cr18Ni9 | SS304 | 12Cr18Ni9 00Cr17Ni12Mo2 | SS304 | 12Cr18Ni9 00Cr17Ni12Mo2 | SS304 SS316 |

Spring | SS304、SS316、InconelX-750 | |||||